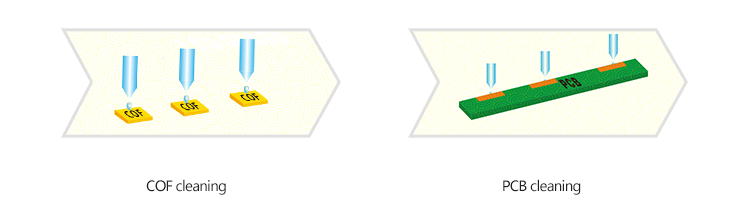

◆COF’s fixture is be moved to center of the machine by manipulator, then it is be fixed.

◆The left platform moves along the X axis to ACF remover region, and the 1# header Z axis falls and first time coating.

◆After first time coating, left platform waits in original 10 seconds (can be set ) then moves to left cleaning area. Cleaning unit falls and moves along X axis to clean ACF ( frequency and speed can be set)

◆When the left platform is in the left cleaning position, the right platform moves to the central position of the machine. The right platform repeats the action of the left platform as above.

◆The first cleaning is done. The left platform moves along the X axis to ACF remover region, and the 2# header Z axis falls and second time coating.

◆After second time coating, left platform waits in original 10 seconds (can be set ) then moves to left cleaning area. Cleaning unit falls and moves along X axis to clean ACF ( frequency and speed can be set)

◆According to process, left platform and right platform can be set, such as time, speed and number etc.

◆Finish coating process, left platform and right platform go back to centre of the machine and alternate refueling.